Although we enjoy the warmth of the fireplace, the odors can be unpleasant. With simple tricks like vinegar, salt, or baking soda, you can keep your home fresh and cozy.

It is an EcoDesign stove (adapted to the new EcoDesign 2022 standards), which has nothing to do with the traditional stoves from the past.

Before diving into the technical details, it is essential to highlight that the installation of a wood-burning stove should be carried out by a qualified professional. While it may seem like a feasible project for a DIY enthusiast, improper installation can lead to significant risks, such as fires or smoke issues. On our website, you can not only purchase your wood-burning stove, but you will also find a list of recommended installers who can help you complete this task safely and effectively.

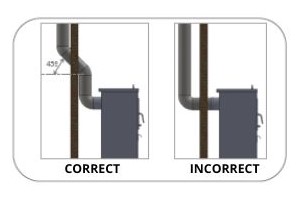

The smoke conducts installed from the smoke outlet of the stove must be as vertical as possible. Horizontal section are not recommended, in case of need elbow joint can be use, however not more than 45º .

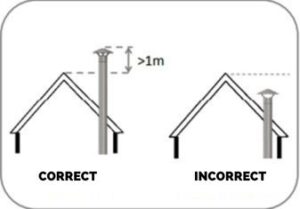

The external exit must exceed the ridge (highest part of the roof) by at least 1 meter. If there is an obstacle within a radius of 5 metres, the exit must exceed this obstacle by at least 1 meter.

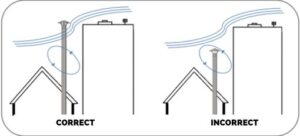

In addition, this exit should be metallic and have a chimney anti –wind cap (like these on the picture) and not of masonry work (the smoke does not have space to go out freely since it also allows the entrance of the wind from the sides):

As also indicated in case the installation is connected to a masonry chimney duct, it is recommended, that the smoke pipes reach till the exterior outlet.

On the other hand, it is important that the outer pipes have double wall (are insulated) to prevent condensation.

The regulations are increasingly demanding in terms of performance (CO emissions below 0.1%, efficiency above 78% …), so it is very important to strictly follow our installation advice.

To achieve these performance requirements, the new stoves are designed in such way to make the passage of smoke more difficult by putting obstacles in its way: such as deflectors or double deflectors, sometimes even triple deflectors. The deflectors serve not only for cooling the smoke on its way out, but also permit the increase of the temperature in the combustion chamber, thus obtaining lower particle emissions and therefore better performance.

To get most of the stove, please follow our recommendation on this video:

The installation for the laboratory tests (for each device) is always the same, since the results obtained depend on the draught of the stove, which in turn depends solely on the installation and the type of used wood. The wood used must be very dry.

At the very first burning in a new fireplace or stove, after the fire has started in the fireplace, we close the fireplace door, but we do not close it on the handle!!! We just leave them shut (about 30 minutes.). This is due to the possible burn of the seal to the fireplace frame. The fireplace is sprayed with a special self-burning paint, so the first time the stove is used, the paint starts to burn and harden. For the paint to burn sufficiently, it is necessary to heat for 3-5 hours, at the manufacturer’s full consumption of wood per hour, which is stated in kilograms.

Attention!!! During firing, the solvents evaporate from the paint. Ventilate the room. The stove can smoke slightly during burning. If you do not “burn” the fireplace enough, you can feel the paint burning for up to 3 uses.

When heating, we first open all the air inlets we have, if we have a chimney flap, we will also open it.

We put a lighter in the fireplace, light it and put it from smaller sticks to bigger ones. We try to place the wood in the back of the fireplace and lean (not throw) against the back wall so that the hot wood does not fall on the glass of the fireplace when it burns out later (it can burst with a bigger impact).

During the first heating, we gradually insert the maximum amount of wood specified by the manufacturer. This creates a hot base in the fireplace, and then we just add as needed – we recommend reloading only when hot embers remain.

After the first load, when the wood starts to burn nicely, we can withdraw the air supply

For combustion, possibly also a chimney flap. But not completely so that it doesn’t start to choke in the fireplace.

How to reload: If we want to add wood, it is necessary to increase the pressure in the fireplace to the chimney before opening the door. So, we open all possible air inlets again, wait a while before the chimney draft increases, and then we unlock the door with the handle, but we don’t open it right away!!!

Let them rest for a moment to equalize the pressure of the fireplace with the room, and then slowly open it and load (we do not open the door abruptly, otherwise due to the quick opening an air current will be created and smoke escapes into the room). We put the wood again to the back wall of the fireplace.

Visit our online shop for wood burning stoves and fireplaces here

Visit our online spare parts shop for your PANADERO wood burning stoves here

Although we enjoy the warmth of the fireplace, the odors can be unpleasant. With simple tricks like vinegar, salt, or baking soda, you can keep your home fresh and cozy.

How to avoid dust in the house when using a wood stove: tips and tricks for a clean and healthy home

Learn how to remove mould from your wood for use by following the steps in this article.

All you need to know: what it is, uses and benefits of wood stoves

To provide the best experiences, we use technologies such as cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique identifiers on this site. Not consenting or withdrawing consent may adversely affect certain features and functions.

From December 19 to January 6, order a wood stove and receive the Helix log holder for free.