How to avoid dust in the house when using a wood stove: tips and tricks for a clean and healthy home

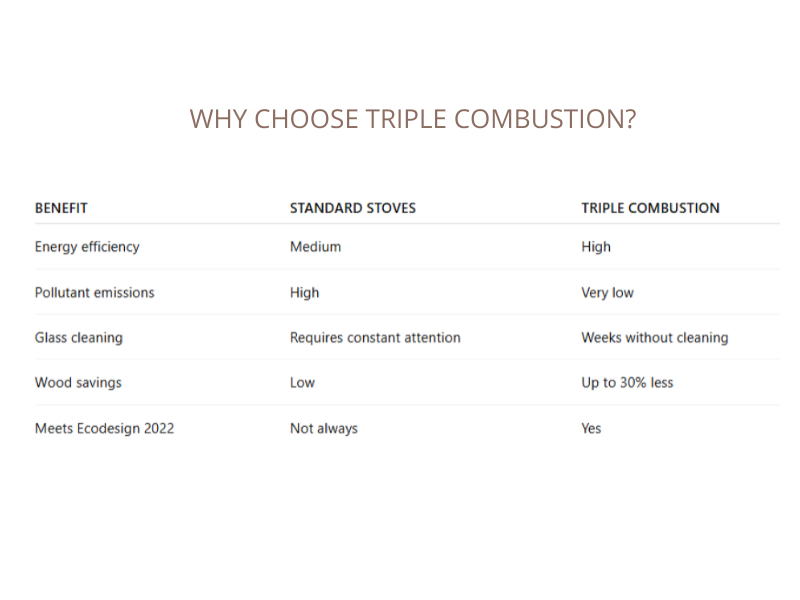

Triple combustion is the technology that takes wood heating to the next level. It’s designed to extract the maximum energy from each log, reducing wood consumption, increasing efficiency, and eliminating most of the pollutants generated in the process.

When you burn firewood, you don’t just release heat. You also release gases and volatile particles. Older stoves expel them straight through the chimney. A triple combustion stove, however, captures them, reignites them, and turns them into more heat and less smoke.

Yes—it’s that simple. And that important.

When wood burns, not everything combusts immediately. Some of it turns into combustible gases and fine particles made up of hydrocarbons and unburned organic matter. If not managed properly, these escape through the chimney as dark gray smoke filled with polluting compounds.

These are the particles that blacken the stove glass, clog the chimney, and—more seriously—harm outdoor air quality.

That’s why Panadero’s triple combustion stoves are designed with a system that traps and re-burns these residues at over 700 °C in a third combustion chamber, transforming them into:

You start the fire with dry wood. This produces an initial wave of heat, but also smoke containing invisible gases and fine particles.

The stove injects preheated air from the top of the chamber. This air reignites the gases, creating more flame, higher temperatures, and significantly less smoke.

This is where it all comes together. A new flow of air is introduced through the rear or upper section of the chamber. This oxygen finishes off what’s left: volatile particles and residual gases. What used to escape as pollution is now transformed into extra heat for your home.

Think of it like making tea. With a regular teabag, you get one cup. With triple combustion, it’s like steeping that same teabag three times—extracting more flavor, more benefits, and leaving almost no waste… without any bitterness.

It’s the same with wood: you don’t need more logs. You just need a smarter stove—like the ones from Panadero.

Triple combustion stoves reduce up to 80% of particulate emissions compared to older models. This means:

And all of this with the peace of mind that it complies with Ecodesign 2022—the European regulation for low-emission, energy-efficient stoves.

BORNEO S.

A vertical, elegant stove that combines powerful performance with modern design. It features triple combustion technology, a built-in log store, and a large combustion chamber for big logs.

INSERT C-720-S.

An insert stove designed to give new life to your old fireplace. With triple combustion and optional ventilation, it transforms an unused cavity into a clean and efficient heating source.

Yes, at www.panadero.com you can find more stoves that include this advanced technology. Just visit the technical sheet of each model to check if it features double or triple combustion. It’s clearly indicated along with other specifications such as efficiency, output, and heating volume.

Reviewing the product details will help you choose the stove that best fits your space and needs.

Yes, if you identify with any of the following:

Panadero’s triple combustion stoves are built for those who love the feel of a real fire—but are done with the problems of the past: dirty smoke, high wood consumption, and constant maintenance.

They’re efficient, clean, safe… and beautiful.

At Panadero, every stove is manufactured in Spain with great care and attention to detail. Because what truly warms a home isn’t just fire—it’s knowing you’ve chosen something well made.

How to avoid dust in the house when using a wood stove: tips and tricks for a clean and healthy home

Learn how to remove mould from your wood for use by following the steps in this article.

All you need to know: what it is, uses and benefits of wood stoves

The flue pipe. The silent piece that makes all the difference. You can have a high-performance wood-burning stove with impeccable design and the best double